| Saturation magnetic induction intensity ( Bs) (T) | 1.56 | Saturation magnetostriction coefficient | 27×10-6 |

| Curie temperature ( Tc) (℃ ) | 400 | Densityd ( g/cm³) | 7.18 |

| Crystallization temperature ( Tx) ( ℃) | 515 | Electrical resistivity ρ(μ Ω-cm) | 130 |

| HardnessHv ( kg/mm²) | 960 |

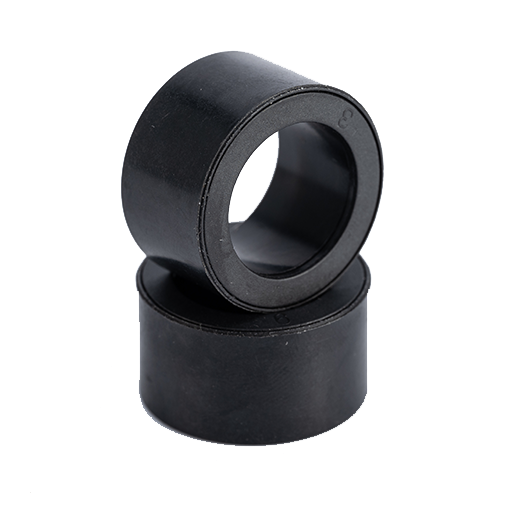

| Product mark | Iron core size (mm) |

Protective box size (mm) |

Rated Current |

Number of turns |

Inductance under OA | Minimum turn inductance under OA | Rated current inductance |

Minimum single-turn inductance under rated current | ||||

| OD | ID | HT | OD | ID | HT | (A) | (N) | (μH) | Min(nH/N²) | (μH) | Min(nH/N²) | |

| BD016010008 | 16 | 10 | 8 | 18 | 8.6 | 11 | 0.5 | 30 | ≥550 | 611 | ≥500 | 556 |

| BD018011010B | 18 | 11 | 10 | 21 | 9.3 | 12 | 1 | 27 | ≥400 | 548 | ≥350 | 480 |

| BD018011008 | 18 | 11 | 8 | 20 | 9.3 | 9.6 | 1 | 24 | 450±20% | 625 | ≥330 | 573 |

| BD018011008B | 18 | 11 | 8 | 20 | 9.3 | 9.6 | 1 | 21 | ≥320 | 725 | ≥250 | 567 |

| BD018010010 | 18 | 10 | 10 | 20 | 8.5 | 13 | 1 | 26 | 565±25% | 626 | ≥400 | 591 |

| BD020012010 | 20 | 12 | 10 | 22 | 9.9 | 12 | 1.8 | 28 | 755±25% | 770 | ≥300 | 382 |

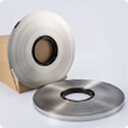

| Performance indicator | AM (250μ) |

MPP (200/300μ) |

AM (550μ) |

MPP (5500μ) |

AM (1500μ) |

Ferrite (1500μ) |

| Saturation magnetic induction intensity ( Bs) (T) |

1.54 | 0.75 | 1.54 | 0.75 | 1.54 | 0.45 |

| Relative initial permeability | 250 | 200/300 | 550 | 550 | 1550 | 1500 |

| Iron core loss( W/Kg) (300mT/5kHz) | 17 | 20 | 10 | 55 | 4 | 9 |

| Iron core loss( W/Kg) (100mT/20kHz) | 11 | 16 | 6 | 40 | 1.2 | 2 |

| Iron core loss(W/Kg) (50mT/100kHz) | 13 | 45 | 9 | 115 | 4 | 2 |

| Iron core loss (W/Kg) (50mT/200kHz) | 31 | 150 | 28 | 313 | 12 | 7 |

| Curie temperature ( ℃) | 400 | 460 | 410 | 460 | 410 | 460 |

| Electrical resistivity(puΩ-cm) | 1.30 | ~10⁴ | 1.30 | ~10⁴ | 1.30 | ~10⁴ |

| Density ( g/m³) | 7.18 | 8.7 | 7.3 | 8.7 | 7.3 | 4.8 |

| Lamination factor | 0.86 | - | 0.86 | - | 0.86 | - |