To understand nanocrystalline split cores, we must first understand their core component—nanocrystalline materials. These materials are alloys prepared using rapid solidification technology, with internal crystal particles only 1-100 nanometers in size, far smaller than traditional magnetic materials. This microstructure endows them with superior magnetic properties.

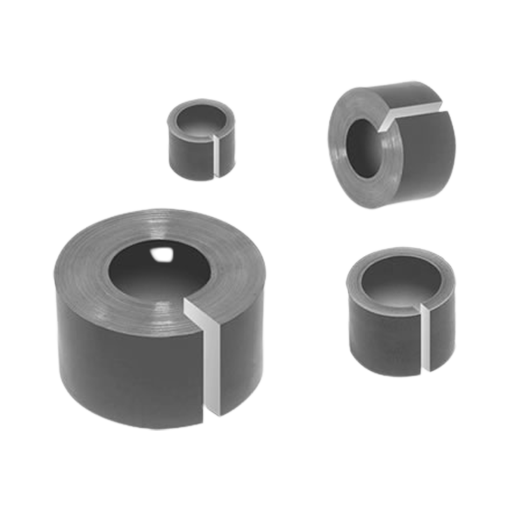

Split cores refer to cores designed as two detachable parts, typically assembled and disassembled using clips or fastening devices.

In power applications, traditional closed cores require pre-installation before the wiring is laid, proving ineffective when dealing with existing wiring or large conductors. The split design solves this problem, allowing core assembly and fixation without disconnecting the wiring, greatly improving installation flexibility and construction efficiency.

The superior magnetic properties of nanocrystalline alloys stem from their unique microstructure, exhibiting particularly outstanding performance in key parameters compared to traditional ferrite and silicon steel sheets.

High permeability is a significant characteristic of nanocrystalline materials, with initial permeability reaching the order of 10⁴-10⁵, far exceeding the hundreds to thousands of permeability of ferrites and the thousands of permeability of silicon steel sheets. This means that nanocrystalline materials can generate strong magnetic induction intensity under weak magnetic fields, making them more sensitive to small signals.

Regarding saturation magnetic flux density, nanocrystalline alloys can reach 1.2-1.5T, slightly lower than high-silicon steel sheets, but far exceeding the 0.3-0.5T of ferrites. This allows them to maintain stable magnetic properties under high magnetic field strengths, making them suitable for high-current applications.

Coercivity is a key indicator for measuring hysteresis loss in materials. The coercivity of nanocrystalline materials is typically less than 10 A/m, far lower than the tens to hundreds of A/m of ferrites and the several A/m to tens of A/m of silicon steel sheets. Extremely low coercivity means minimal hysteresis loss during magnetization and demagnetization, resulting in higher energy conversion efficiency.

In terms of loss characteristics, nanocrystalline materials exhibit significantly lower iron losses than silicon steel sheets in the mid-to-high frequency range (1kHz-1MHz), while overcoming the problem of ferrite materials experiencing a sharp increase in loss at high frequencies, making them particularly suitable for modern high-frequency power electronic equipment.

The core operation of nanocrystalline split cores is based on the principles of electromagnetic induction and magnetic circuit guidance. When current flows through a conductor, a ring-shaped magnetic field is generated around it. The role of the magnetic core is to concentrate these dispersed magnetic fields, forming a closed magnetic circuit, thereby enhancing the magnetic flux of the induction coil.

From a magnetic circuit perspective, nanocrystalline materials, with their high permeability, become excellent pathways for magnetic fields, effectively reducing magnetic leakage and allowing most magnetic lines of force to propagate along the interior of the core. Even in an open structure, the magnetic reluctance can be controlled at a low level in the closed state through precise mating surface design, ensuring the integrity of the magnetic circuit.

During installation, the two parts of the magnetic core are respectively attached to both sides of the conductor. After being secured by a mechanical structure, the mating surfaces are tightly fitted to form a nearly closed magnetic ring. At this point, the conductor, acting as the primary winding, passes through the core window, while the coil wound on the core serves as the secondary winding.

When current flows through the conductor, an alternating magnetic flux proportional to the current is generated inside the core. According to the law of electromagnetic induction, the secondary coil induces a corresponding voltage signal. This signal, after processing, can be used to measure parameters such as primary current and voltage, or to suppress electromagnetic interference.

In the split state, the magnetic circuit of the core is open, with extremely high magnetic reluctance, making it impossible to form an effective magnetic flux loop. When closed, the magnetic reluctance decreases sharply, the magnetic circuit becomes open, and normal electromagnetic conversion is achieved.

Combining the characteristics of nanocrystalline materials with the open-end structure design, these magnetic cores exhibit multiple advantages in practical applications.

High sensitivity is due to the high permeability of nanocrystalline materials. Even minute changes in current or weak magnetic field signals can be captured by the core and converted into significant induced signals, making them suitable for high-precision measurement scenarios.

Easy installation is the core value of open-cell structures. No wire cutting or rewiring is required, enabling rapid installation for both upgrading existing lines and maintaining large equipment, significantly reducing construction costs and downtime.

Strong anti-interference performance stems from its low coercivity and stable magnetic properties. Nanocrystalline materials exhibit stronger resistance to external stray magnetic fields while generating less magnetic interference themselves, maintaining stability in measurement or suppression effects in complex electromagnetic environments.

Compact size is a natural advantage of nanocrystalline materials. For the same magnetic performance requirements, nanocrystalline cores are significantly smaller than ferrite and silicon steel cores, better suited to the miniaturization and integration trends of modern power equipment.

Wide frequency response covers a broad range from power frequency to mid-to-high frequencies. From 50Hz power systems to MHz-level high-frequency electronic equipment, Nanocrystalline Split Cores maintain stable magnetic performance, making them suitable for a wide range of applications.

Due to their superior performance and installation advantages, Nanocrystalline split cores are widely used in overseas power systems and electronic equipment. Core applications include the following:

In current transformers (CTs), nanocrystalline split cores accurately sense primary-side current and proportionally output secondary-side signals for current measurement, metering, and protection, particularly suitable for on-site expansion and retrofitting of power distribution systems.

Residual current devices (RCDs) rely on nanocrystalline cores to sense the current difference between the live and neutral wires. When leakage current causes current imbalance, the change in magnetic flux generated by the core triggers a protection mechanism, achieving rapid power cut-off and ensuring electrical safety.

In common-mode chokes, open-core magnetic cores, combined with windings, form common-mode suppression components, effectively suppressing common-mode electromagnetic interference in the circuit and improving the electromagnetic compatibility (EMC) of communication equipment and power electronic devices.

In power quality monitoring equipment, highly sensitive nanocrystalline split cores accurately capture harmonic components and waveform distortions of voltage and current, providing reliable data support for power quality analysis.

In smart grid equipment, its wide frequency response and high stability meet the stringent requirements of smart metering and remote monitoring for core performance, contributing to the intelligent upgrading of the power grid.

In EV chargers and renewable energy systems, nanocrystalline split cores adapt to the design needs of high frequency and miniaturization, playing a key role in current conversion, energy transmission, and interference suppression, thereby improving system efficiency and reliability.

Selecting a nanocrystalline split core requires considering the specific application scenario and technical requirements, focusing on the following core parameters and characteristics:

Window size is the primary consideration. The core window must be large enough to accommodate the conductor or winding to be monitored, while allowing sufficient installation clearance to prevent direct contact between the conductor and the core, which could affect magnetic properties.

Permeability level needs to be matched to signal strength. For weak signal measurements or low-current scenarios, a high-permeability model should be selected. For high-current or strong magnetic field scenarios, a balance between permeability and saturation flux density is necessary.

AL value (inductance coefficient) directly affects the inductance of the wound coil. The matching AL value must be calculated based on the inductance requirements of the circuit design to ensure that the circuit performance meets design specifications.

Accuracy requirements determine the core's processing precision and material consistency. Metrological applications require high-precision models with uniform magnetic properties and small mating surface gaps. For general interference suppression scenarios, requirements can be relaxed appropriately.

The rated current range must match the maximum operating current in the application to avoid core saturation due to excessive current, which could affect measurement accuracy or damage the equipment.

Regarding mechanical strength, factors such as vibration and temperature changes in the installation environment must be considered. Products with strong snap-fit, high temperature resistance, and aging resistance should be selected to ensure long-term stable operation.

Furthermore, the overall design of the current transformer (CT) or sensor must be considered to ensure that the core size, interface, and circuit topology match to achieve optimal electromagnetic performance.

In terms of magnetic parameters, nanocrystalline split cores have higher permeability and saturation flux density than ferrite cores, and significantly lower coercivity. Compared to amorphous cores, nanocrystalline cores have higher permeability, lower hysteresis loss, and superior magnetic stability.

In terms of operating frequency range, ferrite cores are suitable for mid-to-high frequencies (10kHz-100MHz), but have low permeability at low frequencies; silicon steel sheets are only suitable for power frequencies and low frequencies (50Hz-1kHz); amorphous cores operate at frequencies from 1kHz to 1MHz, but their high-frequency losses are higher than those of nanocrystalline cores; nanocrystalline cores perform best in the 1kHz-1MHz frequency range, exhibiting the lowest losses and wider frequency adaptability.

Regarding loss levels, under the same frequency and flux density conditions, the iron loss of nanocrystalline cores is only 1/5 to 1/10 that of silicon steel sheets and 1/3 to 1/5 that of ferrite cores, with a more significant advantage at high frequencies; the losses of amorphous cores are slightly higher than those of nanocrystalline cores, with the difference widening, especially at high frequencies.

In terms of durability, nanocrystalline materials exhibit superior thermal stability compared to ferrites, with minimal changes in magnetic properties over a wide temperature range of -50℃ to 150℃. Amorphous magnetic cores have lower mechanical strength and are prone to performance degradation due to vibration or impact. Nanocrystalline magnetic cores, after curing and encapsulation, demonstrate superior mechanical stability and anti-aging properties, with a service life exceeding 10 years, meeting the requirements of industrial applications.

Nanocrystalline split cores combine the excellent magnetic properties of nanocrystalline materials with the ease of installation of their split structure, demonstrating irreplaceable advantages in fields such as current measurement, interference suppression, and power quality monitoring. Their wide frequency response, high sensitivity, and low loss characteristics perfectly meet the development needs of modern power electronics and smart grids, making them a core component for improving equipment performance and construction efficiency.