Nanocrystalline materials are alloy materials prepared through special processes such as rapid solidification, with internal crystal particle sizes controlled within the 1-100 nanometer range. This ultra-microstructure distinguishes its physical and chemical properties from conventional crystalline materials, making it particularly outstanding in the field of magnetism.

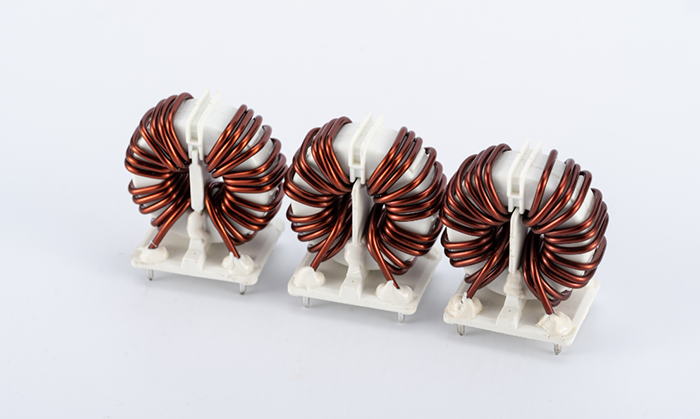

In magnetic device systems, CMC cores (Common Mode Choke cores) are the core components that carry magnetic flux, realize energy conversion, and transmit signals. CMC represents a specific core structure design and fabrication process, giving it a greater advantage in electromagnetic performance control. As the heart of magnetic devices, the core performance directly determines the device's efficiency, size, and reliability.

The core reason why nanocrystalline alloys are the preferred core material is their unique microstructure. The ultra-small crystal particle size significantly reduces the resistance to domain wall movement, while the uniform grain distribution avoids anisotropic fluctuations in magnetic properties, allowing nanocrystalline cores to maintain excellent magnetism while possessing good processing performance.

The fundamental characteristics of nanocrystalline CMC cores can be summarized as "three highs and two lows": high permeability, high saturation flux density, high stability and low coercivity, and low loss. High permeability ensures efficient flux conduction, low coercivity simplifies magnetization and demagnetization processes, and low loss directly improves energy utilization efficiency. These characteristics collectively lay the foundation for their application in power electronics.

High permeability is one of the most crucial performance advantages of nanocrystalline CMC cores. Their permeability typically reaches the order of 10⁴-10⁵, far exceeding that of traditional magnetic materials. This characteristic means that under the same magnetic field strength, it can generate stronger magnetic flux, thereby reducing the number of coil turns and simplifying device structure in design.

Low loss under high-frequency conditions is a significant feature that distinguishes it from traditional magnetic cores. As power electronic equipment moves towards higher frequencies, the loss problem of magnetic cores becomes increasingly prominent. Nanocrystalline CMC cores, by suppressing eddy current and hysteresis losses, achieve losses only 1/3 to 1/5 of traditional ferrite cores in the frequency band from tens of kHz to several MHz.

Excellent saturation flux density ensures the stability of the core under high current conditions. Its saturation flux density can reach 1.2-1.5T, making the core less prone to saturation failure under fluctuating operating current or short-term overload, providing more reliable operation for devices.

Thermal stability and reliability are fundamental requirements for industrial applications. Nanocrystalline CMC cores exhibit a magnetic performance change rate of less than 10% over a wide temperature range of -55℃ to 130℃, adapting to complex industrial and automotive environments with minimal performance degradation after long-term use.

Excellent noise suppression characteristics meet stringent electromagnetic compatibility (EMC) standards. Its high permeability effectively absorbs high-frequency electromagnetic interference signals, converting electromagnetic noise into weak heat energy for dissipation, reducing interference to surrounding electronic equipment.

The magnetic flux conduction mechanism of nanocrystalline CMC cores is based on the directional arrangement of magnetic domains. When an external coil supplies current and generates a magnetic field, the magnetic domains inside the core rotate and rearrange along the direction of the magnetic field, forming an ordered magnetic flux path. This achieves efficient conduction and convergence of magnetic flux, completing the conversion of electrical energy into magnetic energy.

Regarding the reduction of electromagnetic interference, its working principle can be divided into a dual mechanism of "reflection" and "absorption." For common-mode interference signals, the core increases the common-mode inductance through high permeability, reflecting the interference signal back to the interference source. For differential-mode interference, its internal hysteresis loss absorbs and converts the interference energy, achieving interference suppression.

Under different current conditions, nanocrystalline CMC cores exhibit stable adaptability. Under AC conditions, low coercivity reduces hysteresis loss; when facing current pulses, high saturation magnetic flux density allows it to withstand instantaneous large magnetic flux without saturation; in high-frequency environments, the optimized microstructure suppresses eddy currents, ensuring stable magnetic performance.

Compared to traditional ferrite magnetic cores, nanocrystalline CMC cores offer significant performance advantages. In terms of permeability, ferrite cores typically have a permeability on the order of 10³, while nanocrystalline cores can reach the order of 10⁴-10⁵. Regarding saturation flux density, ferrite cores generally have only 0.3-0.5T, far lower than the 1.2-1.5T of nanocrystalline cores. In terms of high-frequency losses, nanocrystalline cores can reduce losses by more than 50% under the same operating conditions.

Compared to amorphous magnetic cores, nanocrystalline CMC cores offer advantages in stability and cost-effectiveness. While amorphous materials possess similarly high permeability, their thermal stability is poor, and temperature changes significantly affect their magnetic properties. Nanocrystalline cores, through crystallization treatment, improve thermal stability by more than 30%. Furthermore, the fabrication process for nanocrystalline materials is more mature, offering greater cost control advantages during mass production.

In the field of power electronics, this advantage directly translates into increased efficiency. Power supplies using nanocrystalline CMC cores can improve energy conversion efficiency by 2%-5%, which translates to significant energy savings for high-power devices. In terms of device miniaturization, the high permeability allows for a reduction in coil turns and core volume; for the same power rating, devices using nanocrystalline cores can be 30%-40% smaller.

Superior frequency response makes them suitable for a wider range of applications. Ferrite cores experience significant performance degradation at high frequencies (>1MHz), and amorphous cores suffer from a sharp increase in losses at mid-frequency frequencies (100kHz-1MHz), while nanocrystalline CMC cores maintain stable performance across a wide frequency range of 10kHz-10MHz, meeting the frequency requirements of various devices.

In power systems, nanocrystalline CMC cores are one of the core components. Switching-mode power supplies (SMPS) utilize their high permeability and low loss characteristics to achieve efficient voltage conversion and stable output; uninterruptible power supplies (UPS) leverage their high saturation flux density to provide stable flux during power outage switching, ensuring power continuity; in photovoltaic inverters, their wide frequency response adapts to the output fluctuations of photovoltaic cells, improving energy conversion efficiency.

In electric vehicle charging and automotive electronics, the advantages of nanocrystalline CMC cores are fully realized. On-board chargers (OBCs) use these cores to meet the demands of small size and high power charging; DC-DC converters (DC-DC converters) utilize their low loss characteristics to improve power supply efficiency and reduce on-board energy consumption; in motor controllers, their anti-interference capabilities ensure stable transmission of control signals.

EMI filters and common-mode inductors are core application scenarios for nanocrystalline CMC cores. With excellent noise suppression characteristics, they effectively filter out electromagnetic interference generated by power electronic equipment, helping equipment meet international EMC standards, and are widely used in computers, communication equipment, and industrial control instruments.

In renewable energy systems, these cores help improve energy utilization efficiency. In wind power converters, high stability adapts to complex outdoor environments; in energy storage system charge/discharge controllers, low-loss characteristics reduce energy losses during storage; in new energy equipment such as tidal and solar power, wide-band adaptability meets the conversion needs of different energy forms.

Industrial automation and control electronic equipment also relies heavily on nanocrystalline CMC cores. In PLC (Programmable Logic Controller) power modules, stable magnetic properties ensure reliable control signals; in the signal transmission circuits of sensors and actuators, high permeability improves signal transmission efficiency; in the drive circuits of industrial robots, low-loss characteristics extend equipment endurance and lifespan.

Matching the required inductance with permeability is the first step in selection. Based on the inductance requirements of the circuit design and the permeability calculation formula, a suitable core specification must be determined—high inductance requirements usually correspond to high permeability cores, but core saturation during operation must be avoided.

Operating frequency and current level directly determine the core's loss and stability. For high-frequency applications, low-loss nanocrystalline cores should be prioritized. For high-current scenarios, the saturation flux density of the core must be carefully considered to ensure it remains unsaturated under maximum operating current.

Operating temperature and thermal requirements are important considerations. Different application scenarios have significantly different temperature environments. The appropriate core product must be selected based on the actual operating temperature range. For high-temperature environments (such as automotive engine compartments), nanocrystalline CMC cores with higher temperature resistance should be selected to avoid performance degradation.

Core size and shape must be adapted to the component structure design. Magnetic cores of different shapes, such as circular, toroidal, and E-shaped, differ in flux distribution and winding convenience. Furthermore, the optimal size must be selected based on the installation space of the equipment, while meeting performance requirements.

Insulation and winding requirements are also crucial. The insulation class of the magnetic core must match the voltage level of the circuit to prevent breakdown and leakage. For scenarios involving thin wires where winding is difficult, a magnetic core structure with more reasonable winding space should be selected to improve production and assembly efficiency.

Overheating is one of the most common challenges. When the magnetic core operates at high frequencies or high currents, if the heat generated by losses cannot be dissipated in time, the core temperature will rise, leading to magnetic performance degradation and creating a vicious cycle of "overheating - performance degradation - increased losses."

Insufficient inductance stability under high-frequency conditions troubles many engineers. As the operating frequency increases, some nanocrystalline magnetic cores experience a decrease in permeability, causing the inductance in the circuit to deviate from the design value, affecting the output stability and control accuracy of the equipment.

Insufficient noise suppression capabilities are particularly prominent in complex electromagnetic environments. When multiple interference sources coexist, improper selection of the magnetic core's permeability or unreasonable installation methods can lead to insufficient interference suppression and prevent the equipment from passing EMC testing.

Installation and winding difficulties are primarily seen in the application of specially shaped magnetic cores. Some miniaturized devices use micro-cores with limited winding space, resulting in low manual winding efficiency and a high risk of wire breakage. Irregularly shaped cores may face issues with inaccurate installation and positioning, affecting magnetic flux conduction.

Material consistency and supply chain issues are crucial to the stability of mass production. Significant fluctuations in permeability, loss, and other indicators between different batches of magnetic cores can lead to a decrease in yield. Furthermore, the stability of the supply of nanocrystalline alloy raw materials can also affect the core delivery cycle.

Improving heat dissipation management can be approached from two aspects: structural design and material selection. Structurally, heat sinks can be added to the outside of the magnetic core, a hollow design can be used to increase the heat dissipation area, or thermally conductive silicone can be used to conduct heat to the device casing. In terms of materials, nanocrystalline materials with lower losses should be selected to reduce heat generation at the source. Magnetic core products with built-in heat-dissipating coatings can also be used.

Optimizing EMI suppression requires combining circuit characteristics with magnetic core parameters. First, a magnetic core with appropriate permeability should be selected based on the interference frequency; for high-frequency interference, products with medium to high permeability should be preferred. Second, the number of coil turns and winding method should be rationally designed, using symmetrical winding to reduce differential-mode interference. Furthermore, combining the magnetic core with a capacitor to form a filter network can further improve interference suppression capabilities.

Matching the magnetic core size with inductance design requirements requires establishing an accurate calculation model. Using magnetic circuit simulation software, parameters such as inductance and operating current are input to simulate the working state of magnetic cores of different sizes, selecting the smallest core size that meets inductance requirements without saturation. For special inductance requirements, magnetic core combinations can be used, adjusting the magnetic circuit length and cross-sectional area by stacking multiple magnetic cores.

Improving reliability in harsh environments requires a dual approach of protection and selection. In high-temperature and humid environments, sealed magnetic cores should be used to prevent moisture and dust intrusion. In vibration environments, the installation stability of the magnetic core should be enhanced through fixing methods such as clips and bolts. Simultaneously, mature products that have undergone environmental reliability testing should be prioritized to ensure stable performance under extreme conditions.

The unique technological value of nanocrystalline CMC cores lies in their organic unity of four key characteristics: high permeability, high saturation flux density, low loss, and wide-temperature stability. This combination of characteristics breaks through the performance bottlenecks of traditional magnetic materials, providing core support for the upgrade of power electronic equipment.

Engineers prioritize nanocrystalline materials essentially in pursuit of a balance between equipment performance and cost. Compared to ferrites, it can improve equipment efficiency and reduce size; compared to amorphous materials, it can enhance stability and reduce the cost of mass production. In the industry trend of high frequency, miniaturization, and high efficiency, nanocrystalline CMC cores have become the optimal solution that balances performance and economy.

Its significance for energy efficiency, safety, and equipment lifespan is immense. Higher energy conversion efficiency directly reduces energy consumption, aligning with global energy conservation and emission reduction initiatives; high saturation magnetic flux density avoids core saturation failure, reducing equipment malfunction risks and improving operational safety; excellent thermal stability and low-loss characteristics slow down core aging, indirectly extending the overall equipment lifespan.

In meeting international EMC standards, nanocrystalline CMC cores play an irreplaceable role. With the increasing frequency of global electronic equipment trade, EMC certification has become a prerequisite for products entering the international market. The superior noise suppression capabilities of nanocrystalline cores help equipment easily pass stringent EMC tests, lowering the technical barriers to export.

Testing core performance indicators is the foundation of quality verification. A hysteresis loop tester is used to plot the B-H curve to evaluate the core's saturation magnetic flux density and coercivity; an impedance analyzer is used to measure permeability at different frequencies to determine its frequency response characteristics; and a loss tester is used to detect the core's loss value under rated operating conditions to ensure compliance with design requirements.

Material consistency testing must cover batch production. Multiple samples from the same batch should be randomly selected, and their magnetic properties tested. The fluctuation range of these parameters should be calculated; for high-quality magnetic cores, the fluctuation in permeability, loss, and other indicators should be controlled within 5%. Simultaneously, microstructural analysis should be used to observe the uniformity of crystal particle size, avoiding performance differences caused by uneven grain distribution.

Overseas customers, in addition to core performance, should also focus on checking environmental adaptability and compliance before purchasing. Thermal stability should be verified through high and low temperature cycling tests, and corrosion resistance should be assessed through salt spray tests to ensure the magnetic core is suitable for the application environment of the target market. Suppliers should also be required to provide RoHS, REACH, and other environmental certification documents to comply with local environmental regulations.

Supplier certification and material traceability systems are crucial for quality assurance. Suppliers certified under the ISO 9001 quality management system should be given priority, and the standardization of their production processes should be assessed. Suppliers should be required to establish a comprehensive material traceability system, achieving full-process traceability from raw material procurement to finished product delivery, ensuring rapid identification of the cause in case of quality problems.

Nanocrystalline CMC magnetic cores, with their unique microstructure and excellent magnetic properties, have become a revolutionary product in the field of magnetic materials. Their advantages in efficiency improvement, size reduction, and noise suppression precisely match the development needs of modern power electronic devices.

In the industry's wave of high-frequency, high-efficiency, and miniaturized devices, nanocrystalline CMC magnetic cores are not only a core support for upgrading device performance but also a key force driving the green development of the power electronics industry. Their application prospects will continue to expand with technological advancements.