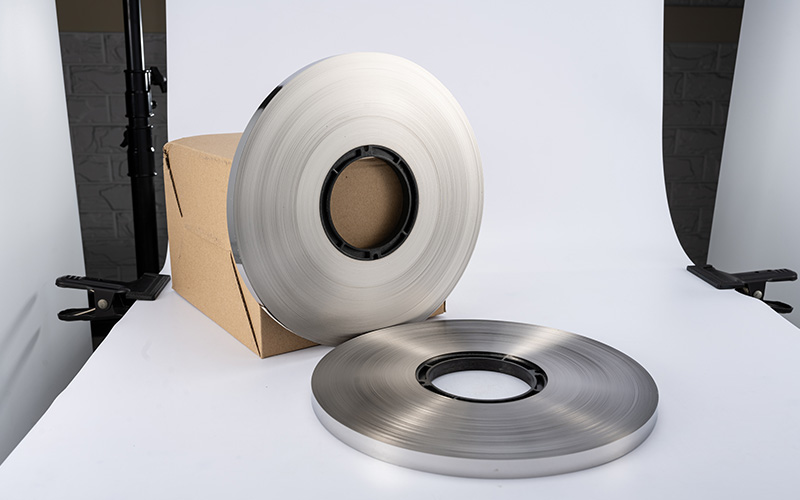

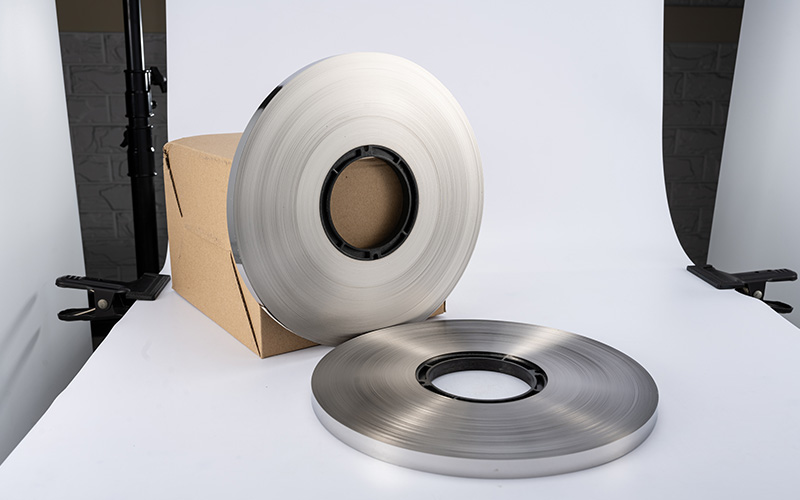

Amorphous is a new type of soft magnetic alloy material. It adopts the international advanced ultra-cold technology to directly cool the molten metal at a speed of one million degrees per second to form an amorphous thin strip with a thickness of 25-35m, and obtain atomic arrangement. The amorphous alloy structure with short-range order and long-range disorder in combination is completely different from traditional metal alloy materials in microstructure. Therefore, traditional metal materials have certain excellent characteristics in many aspects such as physical properties, chemical properties, and mechanical properties. In addition, the preparation process is also completely different from the traditional metallurgical process. The amorphous thin strip is made from molten steel in one step, eliminating the need for multiple processes such as casting, forging, intermediate annealing, and rolling in the traditional metallurgical process, saving energy. A large amount of energy, and no pollutant emissions, amorphous alloys are known as environmentally friendly, energy-saving, high-efficiency new green materials.

The iron-based amorphous ribbon has an ultra-fine crystal column structure. With its high magnetic permeability, high saturation magnetic induction, low iron loss and excellent stability, it can meet the requirements of high-frequency, high-current and small-scale electronic production. It can replace silicon steel, permalloy and ferrite, and is widely used in electric power and electronic products.

Compared with traditional silicon steel transformers, the no-load loss rate of iron-based amorphous alloy transformers is reduced by more than 80%, and the load loss rate is reduced by more than 15%. It has good energy-saving advantages, and its technical threshold is relatively high.