Currently, wireless charging technology has demonstrated a clear trend toward widespread adoption in low-power devices. Wireless charging functionality is increasingly becoming a standard feature in products like smartphones and smart wearables. Looking ahead, its application scope is gradually expanding to medium- and high-power devices. Everyday items such as computers and kitchen appliances, and even large transportation vehicles like electric cars, are expected to utilize wireless charging technology for energy replenishment, with market potential continuing to unfold. As a crucial component of the transmitter and receiver—the core structures of wireless charging systems—soft magnetic materials directly impact charging efficiency and stability.

In this field, materials like ferrites, amorphous alloys, and nanocrystalline alloys compete. As wireless charging demands increasingly higher performance, the differences in material suitability become apparent. Nanocrystalline soft magnetic alloys, leveraging their unique advantages, are occupying an increasingly vital position in this competition.

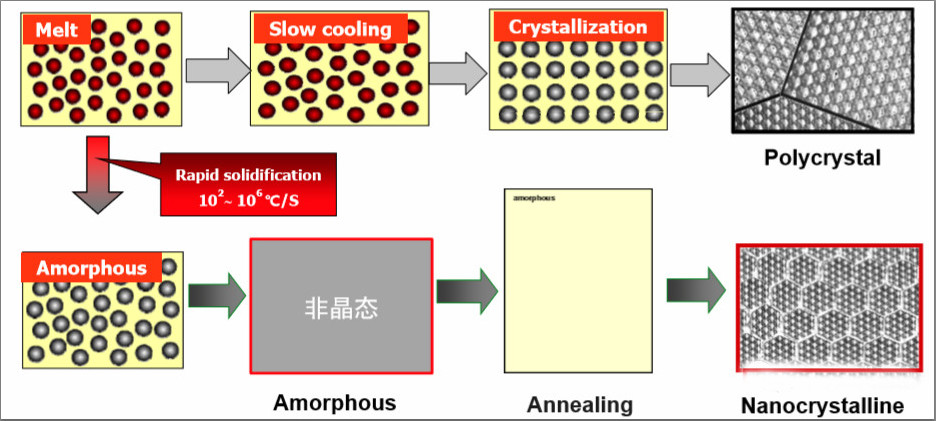

Understanding nanocrystalline materials requires first defining amorphous states. During metal preparation, if solidification occurs at ultra-rapid cooling rates, atoms cannot rearrange in time and remain in a disordered state, instantly frozen—this constitutes the amorphous structure. Nanocrystalline materials, however, are based on the amorphous state. Through specialized heat treatment processes, crystal nuclei are induced to form and grow within the amorphous material. Simultaneously, grain size is strictly controlled to remain below 100 nanometers, ultimately resulting in a hybrid structure where amorphous and nanocrystalline phases coexist.

The preparation principle for amorphous materials is straightforward: the parent alloy is first heated to a molten state, then ejected through a nozzle assembly onto a high-speed rotating cooling roller. This achieves instantaneous solidification, ultimately forming a thin strip with a thickness of only 20-30μm. This process demands extremely precise temperature and speed control: the liquid alloy must reach 1400–1500°C, with cooling rates exceeding one million degrees per second. Strip ejection speeds can reach 30 m/s, while high-precision thickness is achieved through meticulous design of the nozzle slit and roller gap.

The preparation of nanocrystalline soft magnetic alloys, however, is based on amorphous strips. Strips with specific compositions are placed in a heat treatment furnace, where the heating process is directionally controlled to generate grains smaller than 100 nanometers within the strip. This ultimately forms a hybrid structure of amorphous and nanocrystalline phases, resulting in superior magnetic properties.

Nanocrystalline soft magnetic alloys demonstrate outstanding magnetic properties. Their high saturation magnetic flux density facilitates reduced component size, while their excellent magnetic permeability can be flexibly adjusted within the 1000–30000 range. Additionally, their low loss and low coercivity effectively minimize energy dissipation in magnetic devices.

Regarding temperature adaptability, nanocrystalline soft magnetic alloys exhibit a broader operating temperature range than cobalt-based amorphous alloys and ferrites. Within the common temperature range of -40°C to 120°C, their stability significantly outperforms ferrites, making them suitable for wireless charging applications across diverse environmental conditions.

Design flexibility is another key advantage of nanocrystalline materials. Their anti-saturation magnetic field can be adjusted within the range of 30-350 A/m. In wireless charging designs, this ensures magnetic materials do not reach magnetic saturation at specific operating currents, preventing device shutdown and thereby expanding the application scope of wireless charging.

Regarding saturation magnetic flux density, iron-based nanocrystalline materials slightly underperform iron-based amorphous alloys but significantly outperform cobalt-based amorphous alloys and ferrites, offering greater advantages in wireless charging scenarios demanding higher magnetic flux densities.

In key metrics such as coercivity, initial permeability, saturation magnetostriction coefficient, Curie temperature, and performance variation rate, nanocrystalline soft magnetic alloys comprehensively outperform iron-based amorphous, cobalt-based amorphous, and ferrite materials. Particularly at the mainstream Qi standard frequency (100-200kHz) for current wireless charging, nanocrystalline materials exhibit magnetic permeability comparable to cobalt-based amorphous alloys while significantly exceeding iron-based amorphous alloys and ferrites. Conversely, their losses are markedly lower than both iron-based amorphous alloys and ferrites, demonstrating superior adaptability.

Charging efficiency tests reveal that as material thickness increases, the charging efficiency of nanocrystalline magnetic sheets gradually improves. However, efficiency reaches near saturation at 0.1mm thickness. Therefore, wireless charging module designs need not excessively increase nanocrystalline magnetic sheet thickness, thereby avoiding material cost wastage.

Ferrite magnetic sheets exhibit similar efficiency patterns to nanocrystalline materials—higher permeability and thickness correlate with higher efficiency. Yet at equivalent charging efficiency, nanocrystalline sheets require only half the thickness of ferrite, better meeting device miniaturization demands. Currently, nanocrystalline sheets carry higher costs than ferrite. Domestic enterprises are exploring cost control pathways through technological optimization and scaled production to drive broader adoption.

The evolution of smartphone wireless charging has seen multiple iterations in soft magnetic materials. Initially, ferrite dominated the market. As demands for thinner devices and higher charging efficiency grew, amorphous magnetic sheets were introduced, achieving dual improvements in device aesthetics and performance.

Subsequently, nanocrystalline soft magnetic alloys gradually replaced the amorphous-ferrite combination as the mainstream material due to their more comprehensive performance advantages. Concurrently, smartphone wireless charging capabilities expanded beyond basic charging to integrate functions like near-field communication (NFC), with nanocrystalline materials providing critical support for this functional integration.

In low-power scenarios, beyond smartphones, demand for wireless charging in smart wearables is growing. Nanocrystalline soft magnetic alloys, with their compact size and superior magnetic properties, align well with the design requirements of such devices, ensuring charging efficiency and stability.

In medium-power scenarios, wireless charging requirements are emerging for devices like computers and kitchen appliances. These applications demand higher charging power and efficiency. Nanocrystalline soft magnetic alloys, with their high saturation magnetic flux density and low loss characteristics, are becoming key candidate materials for such scenarios, with related application explorations actively advancing.

In high-power applications, wireless charging for electric vehicles represents a key development focus. This scenario imposes stringent performance requirements on soft magnetic materials, demanding not only high permeability and low loss but also excellent temperature stability and anti-saturation capability. Nanocrystalline soft magnetic alloys align closely with these demands and are poised to play a significant role in the wireless charging of electric vehicles.

As electronic products evolve toward higher frequencies, greater energy efficiency, miniaturization, and integration, the frequency of wireless charging applications continues to rise, driving continuous upgrades in performance requirements for nanocrystalline strips. Regarding thickness, conventional strip production processes typically yield nanocrystalline strips between 22-30μm thick. However, internationally advanced strip manufacturing techniques can now achieve thicknesses of 14-22μm, with breakthroughs in producing even thinner strips. Ultra-thin strips represent a key development trend for nanocrystalline magnetic alloys.

Simultaneously, ribbon performance optimization is advancing, targeting higher permeability and lower losses—enhancing high-Q characteristics—to accommodate higher wireless charging frequencies and meet future demands for high-frequency, high-efficiency applications.

The transformation in mass production processes for magnetic sheets has significantly driven the application of nanocrystalline soft magnetic alloys. Since achieving mass production, manufacturing processes have transitioned from early sheet formats to coil formats, significantly boosting production efficiency to better meet growing market demand.

Future process optimization will focus on scaling and precision. By refining production workflows and enhancing equipment accuracy, manufacturers will simultaneously increase efficiency and control costs, laying the groundwork for widespread adoption of nanocrystalline soft magnetic alloys.

From a functional integration perspective, wireless charging technology will deeply integrate with features like near-field communication, enabling multi-functional collaboration within a single device. The properties of nanocrystalline soft magnetic alloys will provide the material foundation for this integration, driving devices toward multifunctionality and integration.

Power enhancement represents a key development direction for wireless charging. Current power levels have evolved from early 5W slow charging to 7.5W and 10W standard charging, and are advancing toward 15W and higher fast charging and flash charging. The high permeability and low loss characteristics of nanocrystalline soft magnetic alloys will support the realization of higher-power wireless charging technologies.

In terms of application scenarios, wireless charging will progressively cover multiple domains including homes, offices, public spaces, and transportation, forming a comprehensive wireless charging network. As a core material, nanocrystalline soft magnetic alloys will play a pivotal role in building this wireless ecosystem.

With its outstanding magnetic properties, temperature adaptability, and design flexibility, nanocrystalline soft magnetic alloy has become the core supporting material for wireless charging technology development. From material iteration to application expansion and technological advancement, it continuously drives improvements in wireless charging efficiency and application scope. Looking ahead, as technological optimization and cost control progress, nanocrystalline soft magnetic alloy will further accelerate the adoption of wireless charging technology, laying a solid foundation for realizing the wireless world.