In power systems, transformers serve as core equipment for energy transmission and distribution, and their operating efficiency directly impacts the energy consumption and economic viability of the entire power network. The transformer core, a key component of the magnetic circuit, is a core material that determines transformer losses, efficiency, and performance. Core material characteristics such as magnetic permeability, loss characteristics, and stability are closely linked to not only the transformer's operating costs but also the overall energy efficiency of the power system.

With the acceleration of global energy transition and the increasing demand for energy conservation and emission reduction in line with the "dual carbon" goals, traditional transformer core materials face increasing performance challenges. Amorphous Cores and cold-pressed grain-oriented silicon steel (CRGO) cores, the two most widely used core materials in transformers, exhibit significant differences in performance, cost, and applicable scenarios. Therefore, a systematic comparative analysis of the characteristics of these two core materials is of great practical significance for transformer selection, energy efficiency optimization, and green transformation in modern power systems, providing key technical reference for power engineering design, equipment manufacturing, and operation and maintenance.

Amorphous Cores are transformer core materials made from thin ribbons of amorphous alloys. Amorphous alloys, also known as metallic glasses, exhibit a disordered atomic arrangement and lack the regular lattice structure of traditional crystalline materials. These alloys typically contain elements such as iron, silicon, boron, and phosphorus as their primary components. Through a specialized rapid solidification process (cooling rates exceeding 10⁶°C/s), the molten alloy is directly formed into thin ribbons as thin as 25-35μm, resulting in an amorphous structure.

1.2 Manufacturing Process

The manufacturing process of Amorphous Cores consists of three key steps:

First, ribbon shearing: The rolled amorphous alloy ribbon is precisely cut to the core's designed dimensions. Due to the brittle nature of amorphous alloy ribbon, the shearing process requires strict control of precision and force to prevent ribbon breakage and stress.

Second, lamination: The sheared ribbon is stacked or rolled into core components such as the core legs and yoke using a specific lamination method (such as stepped lamination or winding) to ensure the continuity and uniformity of the magnetic circuit.

Finally, heat treatment: The formed core undergoes a low-temperature annealing treatment (typically at 300-400°C). This treatment eliminates internal stresses generated during the manufacturing process, improves magnetic properties, reduces core losses, and enhances ribbon toughness and mechanical stability.

The most notable characteristic of Amorphous Cores is their high resistivity, typically 3-5 times that of CRGO silicon steel. This high resistivity effectively suppresses the generation and flow of eddy currents, significantly reducing eddy current losses.

Secondly, the thin ribbon structure (only 25-35μm thick) further reduces the cross-sectional area of the eddy current path. This, combined with the high resistivity, results in Amorphous Cores with total core losses (including hysteresis and eddy current losses) far lower than those of conventional core materials.

Furthermore, Amorphous Cores exhibit excellent magnetic permeability, enabling high magnetic flux at low magnetic field intensities. Their narrow hysteresis loops minimize hysteresis losses, while also providing excellent magnetic property stability, resulting in minimal loss variation over long-term operation.

Distribution Transformers

Amorphous Core distribution transformers are widely used in medium and low voltage distribution applications, such as 10kV and 35kV, due to their low no-load losses. Distribution transformers operate constantly, often under light or no-load conditions. The low no-load losses of Amorphous Cores can significantly reduce long-term energy consumption, making them particularly suitable for the power distribution needs of urban distribution networks, residential communities, and commercial areas.

Rail Transit

Traction transformers and auxiliary power transformers in rail transit systems (such as subways and light rail) have high requirements for energy efficiency and size. The low losses of Amorphous Cores reduce transformer heat generation and the burden on cooling systems. Their compact structure also helps reduce equipment size, accommodating the limited installation space of rail transit vehicles or ground-based substations.

Data Centers

As high-energy-consuming facilities, data centers place stringent demands on the stability and efficiency of their power supply systems. Amorphous Core transformers can be used in data center power distribution systems. By reducing core losses and energy waste, they help data centers achieve energy conservation and emission reduction goals while ensuring power supply reliability.

Renewable Energy Generation

In renewable energy power generation systems such as wind and photovoltaic power generation, Amorphous Cores can be used in key equipment such as inverters and step-up transformers. Its low-loss characteristics can improve energy conversion efficiency and reduce energy losses during transmission and conversion, contributing to the overall economic and environmental performance of renewable energy power generation systems.

Industry and User Projects

In industrial sectors such as precision manufacturing, electronics, and chemicals, which are sensitive to power quality and energy consumption, as well as in user projects such as large commercial complexes and hospitals, Amorphous Core transformers can meet the needs of high-precision power supply and low-energy operation, providing stable and efficient power support for production and daily life.

CRGO core, or cold-pressed grain-oriented silicon steel core, is a transformer core material made by stacking cold-pressed grain-oriented silicon steel sheets. Cold-pressed grain-oriented silicon steel, also known as cold-rolled grain-oriented electrical steel, is primarily composed of iron and silicon (typically with a silicon content of around 3%). Through a specific rolling and annealing process, the crystal grains in the silicon steel sheets are highly oriented along the rolling direction, resulting in a material with excellent magnetic properties.

The core of the CRGO core manufacturing process lies in the production of silicon steel sheets and core lamination:

In the silicon steel sheet production process, hot-rolled silicon steel coils are first cold-rolled. Through multiple cold-rolling passes, the steel sheet thickness is reduced to 0.23-0.3mm (common specifications) and the grains are initially oriented. Continuous annealing then occurs under specific temperature (usually 800-1000°C) and atmospheric conditions to further grow the grains and align them along the rolling direction, forming a clearly oriented structure. Finally, the annealed silicon steel sheets are coated with an insulating layer to reduce inter-sheet eddy current losses.

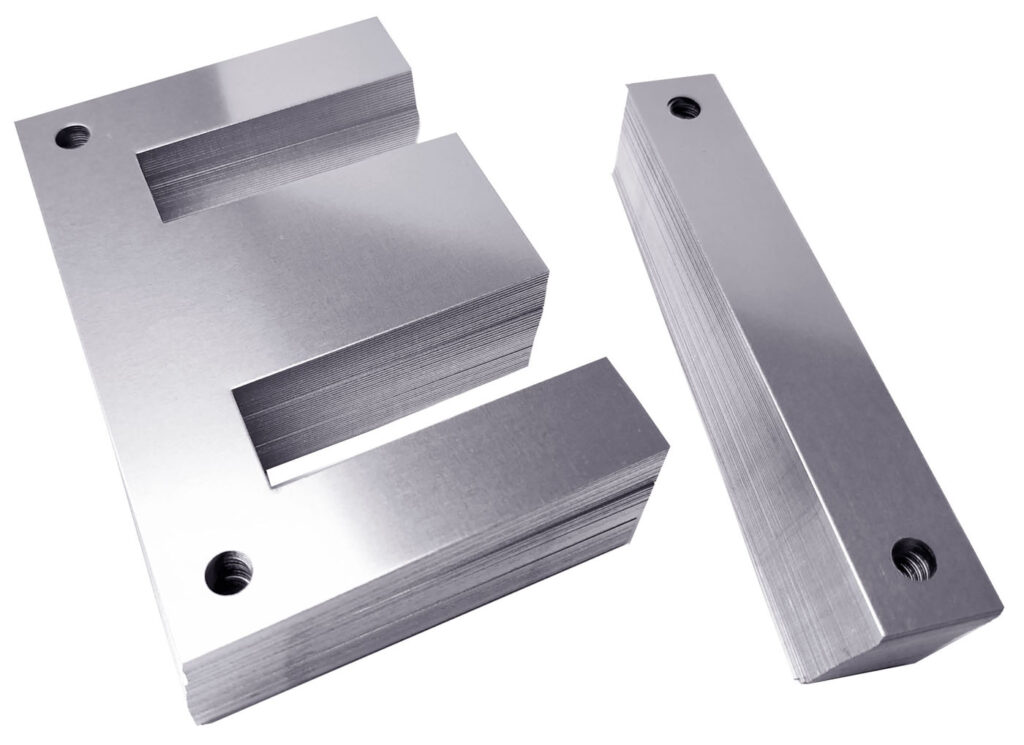

In the core lamination process, the cut CRGO silicon steel sheets are stacked in a "staggered lamination" pattern to form the core. This means that the joints between adjacent layers are staggered to avoid continuous air gaps in the magnetic circuit and ensure smooth magnetic flux transfer. Fastening devices (such as tie bands and screws) secure the laminations to ensure the core's structural stability.

The core advantage of CRGO cores lies in their high magnetic flux density. Under the same magnetic field intensity, their magnetic flux density is significantly higher than that of Amorphous Cores, enabling them to achieve high magnetic flux within a smaller core volume. Therefore, they are suitable for applications requiring high core volume and capacity.

Secondly, the manufacturing process for CRGO silicon steel sheets is mature, resulting in stable product performance. CRGO silicon steel sheets in various specifications (such as high magnetic induction and low loss grades) can meet the requirements of transformers of varying power ratings.

Furthermore, CRGO cores possess excellent mechanical strength. The toughness of silicon steel sheets is higher than that of amorphous alloy ribbons, making them less susceptible to damage during manufacturing, transportation, and installation. The cores also offer excellent vibration resistance and robust operational stability.

Power Transformers

CRGO cores dominate high- and ultra-high-voltage power transformers, such as 110kV, 220kV, and 500kV. This type of transformer typically features large capacity and long transmission distances, placing stringent requirements on magnetic flux density and core volume. The high magnetic flux density of CRGO cores meets the demands of large-capacity magnetic circuit designs, while the sophisticated manufacturing process ensures long-term stable operation under high-voltage, high-load conditions.

Distribution Transformers

CRGO core distribution transformers continue to be widely used in medium and low-voltage power distribution. For high-load, cost-sensitive areas (such as rural distribution networks and temporary power distribution in industrial parks), CRGO core distribution transformers offer significant cost advantages. Their performance meets basic power distribution needs, making them highly competitive in these applications.

Industrial Electrical Equipment

CRGO cores are also a common magnetic circuit material in industrial electrical equipment such as motors, reactors, and welding machines. For example, large industrial motors require an iron core to convert electrical energy into mechanical energy. The high magnetic flux density and stable magnetic properties of the CRGO iron core can ensure the motor's output power and operating efficiency. The CRGO iron core in the reactor can effectively suppress harmonics in the power grid and improve power supply quality.

Amorphous Cores are made from thin amorphous alloy ribbons, whose atoms form a disordered, amorphous structure. They are composed primarily of iron, silicon, boron, and phosphorus. Rapid solidification disrupts the conditions for crystal formation, ultimately creating an amorphous structure.

CRGO cores, on the other hand, are made from cold-rolled, oriented silicon steel sheets, a crystalline material with a regular atomic lattice structure. Their primary components are iron and silicon. Cold rolling and annealing orient the grains in specific directions, creating an oriented structure.

The magnetic performance advantages of Amorphous Cores lie in low losses and high resistivity. Their resistivity is approximately 1.3-1.5 μΩ·m, about three times that of CRGO silicon steel (approximately 0.45-0.55 μΩ·m). This high resistivity significantly reduces eddy current losses. Furthermore, amorphous alloys have narrow hysteresis loops and low hysteresis losses. The overall core losses (no-load losses) are only 1/3-1/5 of those of a CRGO core transformer of the same capacity. This loss advantage is particularly pronounced under low-load and no-load conditions. The highlight of the CRGO core's magnetic performance is its high magnetic flux density: at a magnetic field strength of 1.5T, the magnetic flux density of CRGO silicon steel sheets can reach 1.8-2.0T, while the magnetic flux density of amorphous alloy ribbons at the same magnetic field strength is approximately 1.5-1.6T. This higher magnetic flux density allows the CRGO core to be designed with a smaller cross-sectional area, thereby reducing the size of the transformer, making it more suitable for large transformers with high capacity and volume requirements.

3.3 Cost Difference

In terms of material and processing costs, Amorphous Cores are significantly more expensive than CRGO cores. The production process for amorphous alloy ribbons is complex, requiring significant investment in rapid solidification equipment and requiring high raw material purity, resulting in material costs approximately two to three times that of CRGO silicon steel sheets. Furthermore, the brittle nature of amorphous alloy ribbons necessitates high precision and processing difficulty during the shearing and lamination processes, further increasing manufacturing costs. This results in the initial purchase cost of an Amorphous Core transformer typically being 15% to 30% higher than that of a CRGO core transformer of the same capacity.

CRGO cores, on the other hand, offer significant cost advantages. The manufacturing process for CRGO silicon steel has matured over many years, resulting in high production efficiency, an abundant raw material supply, and lower material costs. Furthermore, the shearing and lamination processes for silicon steel sheets are simple, resulting in low processing costs. Consequently, CRGO core transformers have a lower initial purchase cost and are more widely used in the market.

In terms of operating efficiency, Amorphous Cores perform superiorly: Due to their low core losses, Amorphous Core transformers are more efficient than CRGO core transformers under full-load, part-load, and no-load conditions. This efficiency advantage is particularly pronounced under no-load and light-load conditions (such as distribution transformers operating at long-term light loads). For example, for a 10kV, 500kVA distribution transformer, the no-load losses of an Amorphous Core transformer are approximately 0.3-0.5kW, while those of a CRGO core transformer are approximately 1.5-2.0kW. Over long-term operation, Amorphous Core transformers can save significant energy.

While the efficiency of CRGO core transformers meets the requirements of conventional power systems, they are relatively low: their core losses are higher, especially under no-load and light-load conditions, where they contribute significantly to the overall operating efficiency. However, under high-load conditions (such as when a power transformer is operating at full load), the copper losses (winding losses) of CRGO core transformers increase, while the impact of core losses decreases. The efficiency gap between the two types narrows, but Amorphous Core transformers still maintain a certain efficiency advantage.

From a long-term environmental perspective, Amorphous Cores offer greater environmental advantages: their low losses mean they consume less electricity during operation, reducing emissions of pollutants such as carbon dioxide and sulfur dioxide from thermal power generation, thus helping to lower the carbon footprint. It is estimated that a 10kV, 500kVA Amorphous Core distribution transformer can reduce carbon dioxide emissions by approximately 1.2-1.8 tons annually compared to a CRGO core transformer of the same capacity, making a significant contribution to the environment over the long term.

Due to the higher losses of CRGO core transformers, they waste more electricity during operation, indirectly increasing pollutant emissions and energy consumption. Although the production process of CRGO silicon steel consumes less energy and emits less pollutants than amorphous alloy ribbon, from a lifecycle perspective, Amorphous Core transformers still offer superior environmental benefits in terms of energy conservation and emission reduction.

The application scenarios of Amorphous Cores focus more on high efficiency, energy conservation, and environmental protection. In renewable energy power generation systems (wind power and photovoltaic step-up transformers), they can improve energy conversion efficiency. In smart grids and urban distribution networks, they can accommodate the long-term light-load operation of distribution transformers and reduce grid losses. In energy-efficient applications such as data centers, rail transit, and high-end industries, they meet the demands for low energy consumption and high reliability, making them an ideal choice for green power applications.

CRGO cores still dominate the traditional power sector: in high-voltage and ultra-high-voltage power transformers, their high magnetic flux density characteristics can meet large-capacity transmission needs; in cost-sensitive rural distribution networks, temporary power supply projects and some industrial equipment, the cost advantage of CRGO core transformers makes them the first choice; in addition, in electrical equipment such as motors and reactors, CRGO cores are still widely used due to their mature application experience and stable performance.

When choosing between an Amorphous Core and a CRGO core, multiple factors must be considered, including the application scenario, budget, energy-saving goals, and lifecycle costs. This ensures that the selection meets actual needs while achieving a balance between economic efficiency and environmental performance.

For applications requiring high energy efficiency and long-term equipment operation, such as renewable energy generation (wind power, photovoltaics), smart grids, urban distribution networks, data centers, and rail transit, Amorphous Cores are recommended. In these scenarios, the long-term operational characteristics of the equipment fully leverage the low-loss advantages of Amorphous Cores, achieving significant energy savings.

For applications involving high-voltage/ultra-high-voltage power transmission, cost-sensitive rural distribution networks, temporary power supply projects, or industrial equipment with high magnetic flux density requirements, such as motors and reactors, CRGO cores are more suitable. Their high magnetic flux density and cost advantages meet the capacity, volume, and cost requirements of these applications.

If the project has a sufficient initial budget and focuses on long-term energy savings, Amorphous Cores are a preferred option. While Amorphous Core transformers have a higher initial purchase cost, their low losses over long-term operation can result in significant electricity cost savings, typically paying back the initial cost difference within 3-5 years.

If the project has a limited initial budget and low requirements for long-term energy savings, CRGO cores are more budget-friendly. The low initial purchase cost of CRGO core transformers effectively controls initial project investment and is suitable for cost-sensitive projects with short equipment lifecycles.

If the project has clear energy conservation and emission reduction goals (such as achieving "dual carbon" standards, green building certification, or energy efficiency rating requirements), Amorphous Cores are a must-have. Their low losses can directly reduce equipment energy consumption, helping the project achieve its energy conservation goals while minimizing environmental impact and enhancing its green attributes.

If the project has a more modest energy conservation goal and only needs to meet basic energy efficiency standards, CRGO cores can meet the needs. Although losses are relatively high, with proper design and selection, they can still meet national energy efficiency standards, making them suitable for conventional projects where energy conservation requirements are less stringent.

From the perspective of life cycle cost (initial purchase cost + operation and maintenance costs), Amorphous Cores offer superior overall economic benefits. Taking a 10kV, 500kVA distribution transformer as an example, the initial cost of an Amorphous Core transformer is approximately 50,000-80,000 yuan higher than a CRGO core, but it saves approximately 15,000-20,000 yuan in electricity bills annually, resulting in a total cost savings of approximately 200,000-350,000 yuan over a 20-year life cycle.

While CRGO core transformers offer lower initial costs, their high losses over long-term operation lead to higher electricity bills, resulting in higher life cycle costs than Amorphous Core transformers. Therefore, for equipment with long operating cycles and high usage frequency, Amorphous Cores offer more pronounced life cycle economics.

Amorphous Cores and CRGO cores each have their own advantages and disadvantages. The former offers low losses, high energy efficiency, and environmental friendliness, but also comes at the expense of high costs and low magnetic flux density. The latter offers high magnetic flux density, low costs, and mature technology, but also high losses. When selecting a core, the former is preferred for green power projects, while the latter is suitable for traditional power transmission. As energy-saving standards rise, the application of Amorphous Cores will expand, while CRGO cores will maintain a stable share in high-voltage and other applications.